Lihlahisoa

-

OEM 128-5.0 _ 5.08 pini ea koporo ea boleng bo botle ba PCB screw terminal block_

Monyetla 1. Khetho e ruileng ea sehokelo, basebetsi ba fetang 100 ba nang le boiphihlelo ba ho lokisa hlobo Thepa e tsoang kantle ho naha ho tsoa Japane, Jeremane, Switzerland, Taiwan 2. E sebetsana ka ho khetheha le sehokelo sa tlhahiso ho feta lilemo tse 16 hammoho le ho romella karolo e amehang ho feta lilemo tse 8 3. E-ba le nako e telele le boiphihlelo bo ruileng ba tšebelisano 'moho le Samsung, whirlpool, Midea 4. O batla o fumane mangolo a netefatso bakeng sa sehokelo, joalo ka UL,SGS, MSDS, CE, ISO9001,ROHS,REACH, CQC,TUV, PAHS, PFOS, PFOA ect.Boto ea rona ea ho ea ho bo... -

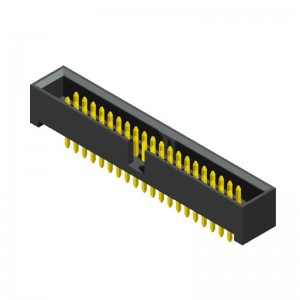

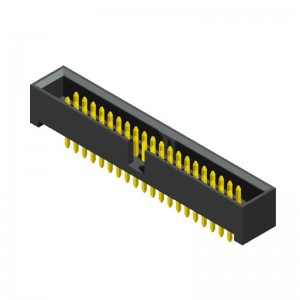

2mm Single Dual Row Connector PCB Board SMT Pin Header _ Pin Header Connector

Hangata lihlooho tsa phini ke lisebelisoa tsa "hole" (THD / THT), empa lisebelisoa tse holim'a metsi (SMD / SMT) le tsona li teng.Tabeng ea SMD, lehlakore la solder la lithapo li kobehile ka lehlakoreng la 90 degree e le hore li ka rekisoa ho lipampiri tsa PCB.

-

PCB 1.27mm Pitch 30 Pin Single Double Row 2.1 Height Straight Dip Smt Pin Header Mohokahanyi oa Hlooho ea Basali

Hlooho ea phini (kapa hlooho feela) ke mofuta oa sehokelo sa motlakase.Hlooho ea phini e motona e na le mela e le 'ngoe kapa ho feta ea lithakhisa tsa tšepe tse entsoeng motheong oa polasetiki, hangata li arohane ka 2.54 mm (0.1 in), leha li fumaneha libakeng tse ngata.Lihlooho tsa li-pin li na le chelete e ngata ka lebaka la bonolo ba tsona.Ka linako tse ling balekane ba basali ba tsejoa e le li-socket headers, leha ho na le mefuta e mengata ea mabitso a lihokelo tsa banna le basali.Histori, ka linako tse ling lihlooho li 'nile tsa bitsoa "li-link tsa Berg", empa lihlooho li etsoa ke lik'hamphani tse ngata.

-

Sehokelo sa Pin Header _ 1.27mm Pitch Shrouded Idc Ejector Header Connector

Litlhaloso tsa 1, Dielectric Withstanding Voltage: 500V AC / DC 2, Insulation Resistance: 1000 Megohms Minimum.3, Contact Resistance: 20mΩ Max Material 1. Bolulo: LCP.Nylon kapa PBT (94V-0), mmala: Black 2. Kopana: Copper alloy gold plating holim'a nickel Name Pin header Spacing 2.54mm Lower board type SMT Color Black Plastic material PA6T Direction Mola o Otlolohileng 1 Kakaretso ea maqhubu 10 Packing Capped Pakete Mocheso o sebetsang -40℃ ho ea +105℃ E lekantsoe hajoale 3.0A W... -

IC Socket Connector 2.54mm 15.24mm DIP IC Sokete e nang le Poso e Bohareng

Li-sockets tsa IC (li-circuits tse kopantsoeng) li sebetsa e le likhokahano tse tsitsitseng pakeng tsa li-circuits tse kopantsoeng (ICs) le liboto tsa potoloho tse hatisitsoeng (PCBs).

-

Pitch 1.778mm Dual In Line IC Socket&Pin Header 16~64P Straight Solder Ic Socket

Tlhaloso ea Sehlahisoa Karolo ea Nomoro ea IC Socket ConnectorPitch 2.54mm Contact Resistance 20mΩ Max Voltage AC 500V/Minute Insulator Thermoplastic UL94V-0 Contact Material Copper Alloy Temperature Range -40° ~ +105° Maemo 6-42 Moun Color Type DIP Theko Nako ea EXW MOQ Likhechana tse 50 Nako ea Pele ea Matsatsi a 7-10 Nako ea Tefo ea T/T, Paypal, Western Union Lihokelo tsena li etselitsoe ho fana ka khokahano e matla lipakeng tsa likarolo tsa likarolo le boto ea potoloho e hatisitsoeng... -

Round Hole IC socket Connector DIP 6 8 14 16 18 20 24 28 40 pin Sockets DIP6 DIP8 DIP14 DIP16 DIP18 DIP20 DIP28 DIP40 phini

Lintho tse bonahalang le plating

Bolulo: PBT&20%Glass Fiber

Likarolo tsa polasetiki: PBT&20%Glass Fiber

Kopana le: Phosphor bronze

Boitsebiso ba ho ikopanya: bronze ea phosphor

-

Speed Precision Stamping Sheet Metal Copper Brass Nickel Spring Steel Terminal, Bracketry, Clamps

Feature Stamping Bokhoni A: The min.sekontiri: 0.5mm B: Lebelo le phahameng ka ho fetisisa la ho hatakela: 600SPM/min kapa ho feta C: Ho nepahala: ± 0.003mm D: Sekhahla sa bophara ba lesoba le botenya 0.85: 1 E: Botenya ba thepa: 0.05-2.0mm F: tahlehelo ea zero kapa ka tlase ho tshebediso ya thepa.thepa Stainless steel, carbon steel, phosphor bronze, brass jj sebetsa lisebelisoa tsa elektronike sehokelo tshebetso Punching Certification ISO 9001:2015, ROHS(SGS) kapa ROHS,IATF 16949:2015 joalo-joalo sebelisa ho Likoloi, mechini, motlakase ... -

Seteishene sa Brass se Iketselitsoeng sa Metal Brass Front le Ka morao Socket Shrapnel Stamping Brass Terminal Bakeng sa Outlet

Feature Superior ho kopana le motlakase.Premium Quality- Lekoa Mocheso.E hanana le corrosion.Khauta ea Brass e Peliloeng Bakeng sa Phallo e Eketsehileng ea Matla.8 Gauge Power Wire/ Ground Wire Ring Terminals.5/16 ″(hoo e ka bang 8.5mm) bophara ba selikalikoe.E sebelisoa haholo sebakeng sa elektronike sa likoloi, lisebelisoa tsa motlakase le likoloi, likepe tsa likepe joalo-joalo Lintho tse fumanehang Carbon steel, Stainless steel, spring steel, Bronze, koporo, alloy ea koporo, alloy aluminium, tinplate, nickel silver Surface treatment zinc / nickel / chr. .. -

Terminal Block Parts _ Stamping Bronze Metal Crimp Wire Terminal preinsulated crimping cable lug terminal

Bokhoni ba ho Stamping A: The min.sekontiri: 0.5mm B: Lebelo le phahameng ka ho fetisisa la ho hatakela: 600SPM/min kapa ho feta C: Ho nepahala: ± 0.003mm D: Sekhahla sa bophara ba lesoba le botenya 0.85: 1 E: Botenya ba thepa: 0.05-2.0mm F: tahlehelo ea zero kapa ka tlase ho tshebediso ya thepa.thepa Stainless steel, carbon steel, phosphor bronze, brass jj sebetsa lisebelisoa tsa elektronike sehokelo tshebetso Punching Certification ISO 9001:2015, ROHS(SGS) kapa ROHS,IATF 16949:2015 joalo-joalo e sebelisoa ho Likoloi, mochini, lebokose la taolo ea motlakase, ... -

Auto Electric Copper Motor Terminal Battery Ring Wire Harness Connectors Crimp Terminal

Re sebelisa mefuta e fapaneng ea mochini oa setempe (sekoaelo ho tloha letsohong ho ea ho punch e nepahetseng) ho hlahisa tšepe le ho tobetsa.Ho latela bongata ba odara ea bareki, re fana ka mokhoa o theko e boima ka ho fetisisa oa projeke ea hau, re ka sebelisa laser cutting, Single-shot kapa continuous progressive die automated production.

-

Ground Ring Terminal 2.5_2.6_2.7 Ground ring terminal O-type terminal

Sebaka se Molemo sa Tšimoloho Dongguan China Mofuta oa Crimp Terminal Brand Lebitso la Yuting Model Nomoro e Tloaelehileng ea Ground Ring Terminal Lebitso la Sehlahisoa sa Ground Ring Terminal Material Brass Plating Tin Certificate CE, ROHS Botenya ba thepa ea rona bakeng sa litšepe tsa rona tsa ferrous le tse se nang ferrous bo tloha ho 0.01mm ho isa 2mm le bophara ba setoko bo tloha ho 10mm ho isa ho 1000mm ka likhetho tse entsoeng esale pele le ho qeta.Re boetse re sebetsa ka mefuta e fapaneng ea lisebelisoa ho fa bareki khetho e kholo ka ho khetheha ...